Customized patient implants have been shown to improve patient outcomes but they typically require increased preoperative assessment, involve longer lead times, and are burdened with higher costs all of which have prevented widespread adoption.

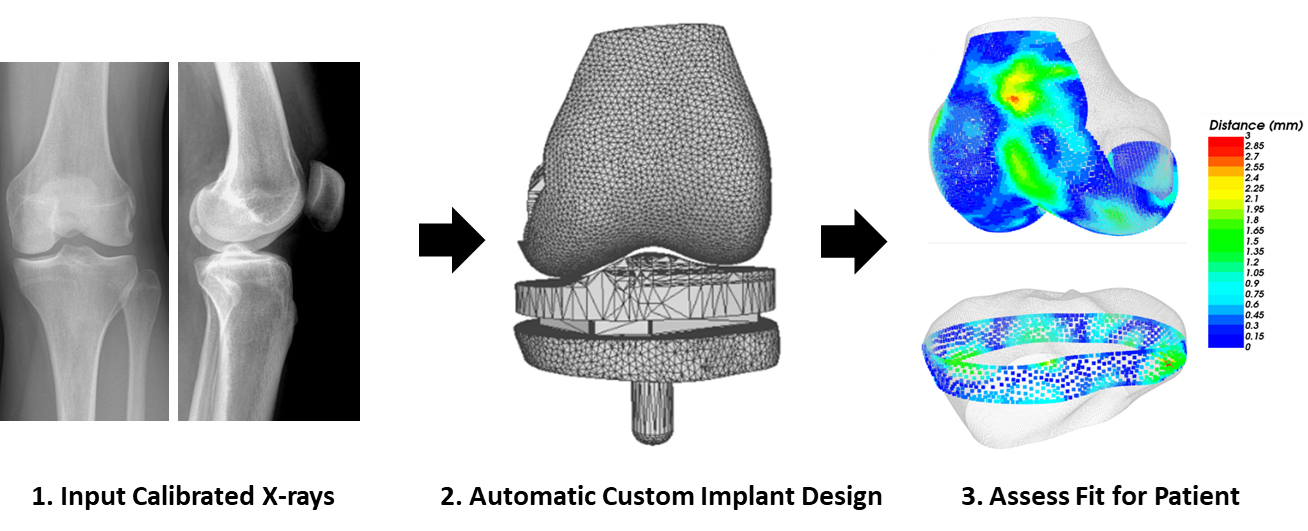

To attain the benefits of patient-specific implants, whilst avoiding the limitations of currently available solutions, fully automated design and manufacture product pipelines are needed. Dr Myant’s group is working to develop the methodologies required for these pipelines, by employing AI processes to handle patient data and drive parametric design processes. In their recent paper, they demonstrate a mass-customization pipeline, capable of developing customized knee implant designs for fabrication via additive manufacturing from calibrated X-rays.

To find out more, access to the research article can be found here.

This article was written by Conner Myant and Thomas Burge, detailing the GSK funded research paper

Reference:

Burge, T. A., Jeffers, J. R. T., and Myant, C. W. (September 15, 2021). “Development of an Automated Mass-Customization Pipeline for Knee Replacement Surgery Using Biplanar X-Rays.” ASME. J. Mech. Des. February 2022; 144(2): 021702. https://doi.org/10.1115/1.4052192